The Process

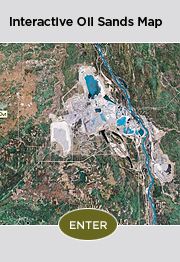

| Only 20 per cent of all oil sands reserves contain bitumen close enough to the surface (less than 70 meters) to be mined using open pit/truck and shovel technology. The remaining 80 per cent of oil sands reserves are located in deeper layers and can only be extracted using in-situ techniques.

Latin for “in place”, in-situ oil sands operations recover bitumen from deep below the Earth’s surface using conventional drilling and wellbore type operations (i.e., no mines, no tailings ponds). In-situ operators use various approaches to reduce the viscosity of the bitumen so that it can flow into a production well. Most major in-situ projects inject high pressure steam through a well, heating the bitumen underground so it can be pumped to the surface. While this is often accomplished by injecting steam, there are also other approaches, including injecting solvents, natural gas liquids, or oxygen, which causes underground combustion that provides the heat to soften the bitumen. Like bitumen produced by mining operations, in-situ bitumen also requires further processing to remove water and sand particles. Recovered solids may be land-filled, injected underground or used to surface roads. In-situ operations are able to achieve water recycle rates of over 90 per cent of the water used, with the remainder remaining underground in the reservoir or being lost as steam. For steam assisted in-situ projects, mainly non-potable groundwater from saline aquifers is used to generate the steam. Pentanes and heavier hydrocarbons obtained from natural gas processing serve as diluents for in-situ bitumen, so it can be shipped by pipeline for further upgrading. In-situ oil sands development disturbs substantially less surface area than mining projects, and requires significantly less land reclamation effort since surface materials are only minimally disturbed. As well, in-situ sites can be reclaimed faster because they do not require the use of tailings ponds. In-situ technology development today is focused around decreasing water and energy use in oil sands operations and increasing bitumen recovery efficiency. To discover what in-situ projects are currently underway, visit the OSDG project status. |