Mining Extraction Method

Fact: Commercial open pit mining has been ongoing in the oil sands for over 40 years.

- Open pit mining of the oil sands first began in the 1920s. The first large-scale commercial operation was introduced by Great Canadian Oil Sands (now Suncor Energy) in 1967.

Fact: Oil sands mining technology has evolved significantly over the years.

- Suncor Energy used bucket wheels from the coal mining industry in its early operations. Bucket wheels were some of the largest vehicles ever built. A large rotating wheel was mounted on a boom, and on the outer edge of the wheel, buckets would remove earth and carry it around to the backside of the wheel where it would fall onto a conveyer that carried it up the excavator.

- Syncrude Canada Limited relied on enormous draglines that were connected to a plant by a network of conveyor belts when it opened in 1978.

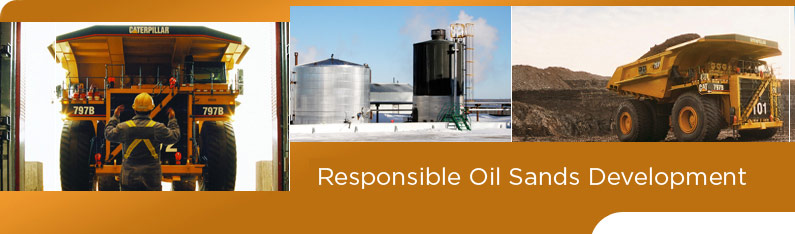

- Today, massive trucks and shovels have replaced draglines and bucket wheels. The trucks can carry up to 400 tonnes of oil sands to separation plants in surface mining operations.

- Hydro-transport has in many cases replaced conveyor belts. Oil sands ore is mixed with water and transported as slurry through pipelines to the processing facility. Bitumen begins to separate out of the sand in the pipeline, making separation more efficient than in the past.

Fact: Oil sands mining requires a series of steps to turn oil sands ore into synthetic crude oil.

- First land is cleared of trees and the overburden is drained and stored to be later used for reclaiming the area.

- Oil sands ore consists of sand, fine clays, water and bitumen. Shovels excavate the oil sands ore and place it into large haul trucks. The trucks haul the ore to a central location and dump it into hoppers where it is ground up and mixed with water. It is then piped via hydro-transport pipeline to the extraction plant where the bitumen is separated from the sand.

- The sand, fine clays and a small amount of unrecovered bitumen, mixed with water, is transferred to settling basins known as tailings ponds while the separated bitumen is sent for further upgrading.

- Bitumen is upgraded into a synthetic crude oil that can then be processed by refineries into end products such as gasoline, diesel or jet fuel.

Fact: Open pit mining projects are large-scale undertakings that require much planning, time and investment while adhering to strict government regulations.

- It takes about 8 to 10 years to bring mining projects into production. This includes the time required to complete engineering feasibility studies, to gain regulatory approval, to complete construction and to start up production facilities.

- Ongoing oil sands projects must receive renewed government operating approval at least every 10 years.

- Typical mining, extraction and upgrading projects require a multi-billion-dollar investment to produce 100,000 barrels per day of high quality synthetic crude oil.

- Oil sands developers must post financial security equivalent to the cost of reclamation before it begins any activity. This money is kept in the Environmental Protection Security Fund and is returned when reclamation certificates are issued. As of June 2008, the fund held more than $720 million.

- One hectare of a surface mine will produce about 10,000 barrels of bitumen.

- About two tonnes of oil sands must be dug up, moved and processed to produce one barrel of oil.

Fact: Mining operations are always employing new technology to improve their environmental and economic performance.

- Replacing draglines and bucket wheels with trucks and shovels has resulted in more efficient operation as it has allowed developers to be more selective in mining.

- Processes such as hydro-transport and low energy extraction have reduced energy use in mining and extraction by about 45 per cent per barrel since 1990. Low energy extraction typically operates at 35 to 40 degrees celsius versus the 80 degree celsius processes emplyed by the industry in the 1980s.

- New technology will reduce the time needed to reclaim tailings ponds and eventually could reduce the volume of tailings or eliminate them altogether.

- More than 80 per cent of the water used during surface mining operations is repeatedly recycled.

Facts sourced by Oil Sands Developers Group (October 2009).

Sources for all facts available upon request.